This is an ongoing project. I am not responsible if you break or otherwise exterminate yourself or your projector using this information :)

I got of ebay a Dell projector with lamps running 2000hrs and above 150$ each. That is quite expensive for my taste especially if one considers that the projector was bought for approximately the same price of a lamp.

I got of ebay a Dell projector with lamps running 2000hrs and above 150$ each. That is quite expensive for my taste especially if one considers that the projector was bought for approximately the same price of a lamp.

So having seen other people modifying their projectors to run on LED light, I started digging.

I sourced in DX.com a supposedly 9000lm, 100W LED light, got the relevant 32-36 volts LED driver and got to work. (After a bit of searching, I found similar items on Ebay but cheaper. I guess I should have searched more.)

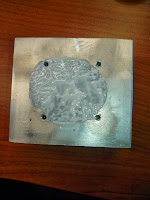

Anyway with the help of a cpu heatsink, a battery drill, a threading tool set, and some thermal grease, I produced the following:

A grinder was used to make two groves on the sides of the cooler for the guides on the projector. Also the cooler was cut in a trapezoid of sorts to fit inside the projector opening. Its not very pretty, but I am happy as it turned out. Especially since everything seems to fit nicely!

According to wikipedia the Intel P4 produces between 68.4 and 85 Watts of heat. So the heatsink should be adequate even if a bit maimed for the 100W LED.

A soldering iron and a few minutes later, the assembled item looks like this:

The cables and plug was sourced from an old air conditioning unit. The screws are standard 3mm computer screws. Although I could cut the long aluminium leads I covered with black nail polish in the hopes that I will avoid any short circuits. Some kapton tape was added for good measure. And the cables were placed together with some heatshrink.

The LED driver was put in a plastic housing. A plug from an old charger was soldered to be able to be used with a common cable, some hot glue was placed in strategic places to keep it steady.

This thing is not going to fit inside the projector, but that is a small problem if you ask me.

The results so far.

This thing is bright! I mean REALLY BRIGHT!!!!!!! I do not have the equipment to measure if it is indeed 9000lm, but seems brighter than the projector lamp which is rated at 4000lm. I should put them side to side for comparison now that the projector still works ;)

The heatsink becomes warm after 1-2 minutes. I didn't want to test it longer without some active cooling.

The positive thing is that the heatsink fins are parallel to the airflow. Will see how that works once I manage to turn the projector on with the LED light source.

Some pics of the space the led and the heatsink must fit. The circular hole is where the light is guided onto the DLP disk colour wheel. While the rectangular white hole on the right is a heat vent to remove the heat from the lap away from the colour wheel.

On the photos above, the fan is located on the lower end of the left photo and the right side of the right photo. The fan blows the hot air out of the projector on the top and left side respectively.

A photo with the heatsink nicely fitted in the slot. I managed (out of pure luck I must say) to make it so that the fit is tight and it is not moving. The fan will blow the hot air parallel to the the heatsink fins.

The heatsink came from a P4 desktop and its dimensions fit nicely into the available space. The think to notice which is not obvious here is that the placement of the LED on the heatsink is not ideal since it is not centered over the color wheel hole. I should make some new holes to position it lower on the heatsink.

A few photos of the original lamp:

From the design of the lamp I understand that the small piece of glass in front of the lamp is probably acting as a heat shield. To reduce the amount of heat the DLP mechanism of the projector feels from the lamp. At the same design principles, there is a small vent with a grating to channel the heat sideways and into a special opening of the projector which can be seen at the photos above.

I was looking for a used Dell lamp to take apart with no luck. It would be nice to use the heatshield glass on the LED, although I am not sure if it is necessary.

I can safely assume that the heat produced from the 100 Watt LED is lower than the heat produced from the 300W original lamp. Though I cant really measure the difference without an IR thermometer or other equipment.

I will attempt a calculation.

According to wikipedia, typical incandescents convert 5% of electricity into light and the rest to heat. If thats approximately correct for this lamp, then 300-5%*300=285Watts of heat are produced from the original lamp.

The LED in comparison according to wikipedia again, converts 70% into heat which for my 100W LED gives 70Watt of heat, or around 1/4th of the incadescent heat production.

Perhaps I shouldn't be concerned with the heat from the LED. I could cover the black plastic area around the colour wheel hole with a reflective material, aluminium paper or tape comes to mind, to avoid it become heat stressed.

Also from wikipedia it is mentioned that a 5000-20000Volt start up current is used to ignite the metal halide lamps in DLP projectors which would explain why my multimeter stopped working after using it to measure the volt-current from the terminals where the bulb plugs. DAMN!

I am having a hard time getting the projector case open without damaging it. While searching for the service manual, i found the Dell ftp site with lots of things inside ftp://ftp.dell.com/ but not the service manual I was looking for.

Some pics of the space the led and the heatsink must fit. The circular hole is where the light is guided onto the DLP disk colour wheel. While the rectangular white hole on the right is a heat vent to remove the heat from the lap away from the colour wheel.

On the photos above, the fan is located on the lower end of the left photo and the right side of the right photo. The fan blows the hot air out of the projector on the top and left side respectively.

A photo with the heatsink nicely fitted in the slot. I managed (out of pure luck I must say) to make it so that the fit is tight and it is not moving. The fan will blow the hot air parallel to the the heatsink fins.

The heatsink came from a P4 desktop and its dimensions fit nicely into the available space. The think to notice which is not obvious here is that the placement of the LED on the heatsink is not ideal since it is not centered over the color wheel hole. I should make some new holes to position it lower on the heatsink.

A few photos of the original lamp:

From the design of the lamp I understand that the small piece of glass in front of the lamp is probably acting as a heat shield. To reduce the amount of heat the DLP mechanism of the projector feels from the lamp. At the same design principles, there is a small vent with a grating to channel the heat sideways and into a special opening of the projector which can be seen at the photos above.

I was looking for a used Dell lamp to take apart with no luck. It would be nice to use the heatshield glass on the LED, although I am not sure if it is necessary.

I can safely assume that the heat produced from the 100 Watt LED is lower than the heat produced from the 300W original lamp. Though I cant really measure the difference without an IR thermometer or other equipment.

I will attempt a calculation.

According to wikipedia, typical incandescents convert 5% of electricity into light and the rest to heat. If thats approximately correct for this lamp, then 300-5%*300=285Watts of heat are produced from the original lamp.

The LED in comparison according to wikipedia again, converts 70% into heat which for my 100W LED gives 70Watt of heat, or around 1/4th of the incadescent heat production.

Perhaps I shouldn't be concerned with the heat from the LED. I could cover the black plastic area around the colour wheel hole with a reflective material, aluminium paper or tape comes to mind, to avoid it become heat stressed.

Also from wikipedia it is mentioned that a 5000-20000Volt start up current is used to ignite the metal halide lamps in DLP projectors which would explain why my multimeter stopped working after using it to measure the volt-current from the terminals where the bulb plugs. DAMN!

I am having a hard time getting the projector case open without damaging it. While searching for the service manual, i found the Dell ftp site with lots of things inside ftp://ftp.dell.com/ but not the service manual I was looking for.